Add to Cart

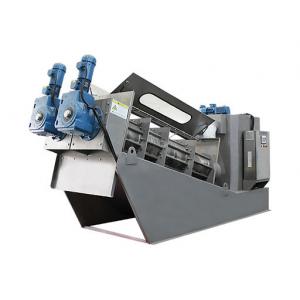

The Multi Disc Screw Press, also known as the Screw Press for Multiple Discs or the Multi-Disc Dewatering Screw Press, is a revolutionary product designed for efficient and reliable dewatering of various materials. It is ideal for use in industries such as wastewater treatment, food processing, mining, and more.

The Multi Disc Screw Press is a robust and versatile machine that combines the functions of thickening and dewatering in one unit. It is designed to handle a wide range of materials, including sludge, industrial waste, and food waste, with ease and efficiency.

The machine is made of high-quality stainless steel material, ensuring durability and corrosion resistance. It is equipped with a PLC control system, providing precise and accurate control over the dewatering process. The noise level of the machine is low, making it suitable for use in various settings.

The Multi Disc Screw Press is available in a range of sizes, with a net weight ranging from 230kg to 6900kg. This makes it suitable for use in both small and large-scale operations, providing flexibility and convenience to the users.

The machine is equipped with a drum of varying sizes, with a mud cake outlet distance ranging from 265mm to 801mm. This allows for efficient separation and disposal of the dewatered material.

The Multi Disc Screw Press is an innovative and efficient solution for dewatering various materials. With its high-quality construction, precise control system, and low noise level, it is the ideal choice for industries looking for a reliable and cost-effective dewatering solution.

| Product Name | Screw Press for Multiple Discs |

|---|---|

| Noise Level | Low |

| Material | Stainless Steel |

| Control System | PLC |

| Treating Capacity | High |

| Net Weight(kg) | 230-6900 |

| Mud Cake Outlet Distance(mm) | 265-801 |

| Product Name | Screw Press for Multiple Discs |

|---|---|

| Noise Level | Low |

| Material | Stainless Steel |

| Control System | PLC |

| Treating Capacity | High |

| Net Weight(kg) | 230-6900 |

| Mud Cake Outlet Distance(mm) | 265-801 |

DUBHE Multi Disc Screw Press is a revolutionary product designed and manufactured in China. It is a highly efficient and low-noise sludge dewatering equipment that has gained wide recognition in the industry. Made with superior quality stainless steel, this product offers unmatched performance and durability.

DUBHE Multi Disc Screw Press is proudly made in China. Our state-of-the-art manufacturing facilities and skilled workforce ensure that each product meets the highest standards of quality and efficiency. We take great pride in contributing to the development of China's industrial sector and delivering top-notch products to our global customers.

The Multi Disc Screw Press is equipped with a special drum that has a range of outlet distances from 265mm to 801mm. This allows for efficient separation and dewatering of sludge, resulting in a high-quality and dry mud cake. The adjustable outlet distance also ensures that the equipment can be customized to suit the specific needs of different applications.

DUBHE Multi Disc Screw Press is designed to handle high volumes of sludge with ease. With its advanced screw dewatering technology, it can treat large quantities of sludge in a short period of time. The high treating capacity of this product makes it a perfect choice for industries that generate a large amount of sludge on a regular basis.

Noise pollution is a major concern in industrial settings. DUBHE Multi Disc Screw Press is designed to operate at a low noise level, making it ideal for use in noise-sensitive environments. This feature not only ensures a peaceful work environment but also helps in complying with noise regulations set by authorities.

The Multi Disc Screw Press is equipped with a state-of-the-art PLC (Programmable Logic Controller) system. This advanced control system allows for precise and efficient operation of the equipment. It also offers remote monitoring and control capabilities, making it easier for operators to monitor the performance of the equipment and make necessary adjustments.

DUBHE Multi Disc Screw Press is made with high-grade stainless steel, which offers excellent resistance to corrosion, wear and tear, and temperature changes. This ensures the longevity of the equipment and makes it suitable for use in harsh industrial environments. The use of stainless steel also ensures that the dewatering process is hygienic and safe for the operators.

DUBHE Multi Disc Screw Press is a versatile product that can be used in a wide range of industries and applications. Some of the common applications of this product include:

Some of the scenarios where the Multi Disc Screw Press is highly beneficial include:

DUBHE Multi Disc Screw Press offers a cost-effective and efficient solution for sludge dewatering, making it an essential equipment for various industries. With its high treating capacity, low noise level, and advanced control system, this product is a must-have for any industrial setting.

The Multi Disc Screw Press from DUBHE is a highly efficient and customizable solution for dewatering and solid-liquid separation. With its multiple disc design, it offers superior performance and flexibility in various industrial applications.

The Multi Disc Screw Press is designed to operate with minimal noise, making it suitable for use in both indoor and outdoor settings without causing any disturbance.

The weight of the Multi Disc Screw Press varies depending on the model and customization options chosen, allowing for a wide range of options to meet different requirements and preferences.

The Multi Disc Screw Press is equipped with a state-of-the-art PLC control system, offering advanced automation and control capabilities to ensure smooth and efficient operation.

The outlet distance of the mud cake can be customized between 265-801mm, providing flexibility to meet specific project needs and achieve optimal performance.

The Multi Disc Screw Press has a high treating capacity, making it suitable for large-scale industrial operations and capable of handling high volumes of sludge and wastewater.

At DUBHE, we understand that every project has unique requirements and challenges. That's why we offer a wide range of customization options for our Multi Disc Screw Press to meet specific needs and achieve optimal results. Our team of experts will work closely with you to develop a customized solution that best fits your needs and budget. Contact us today to learn more about our customization services.

The Multi Disc Screw Press will be carefully packaged to ensure safe and secure delivery to our customers. The packaging will include:

Our team will also conduct quality checks before packaging to ensure that the product is in good condition and ready for shipping.

For shipping, we use reliable and reputable carriers to deliver the Multi Disc Screw Press to our customers in a timely and efficient manner. This may include air, sea, or land transportation depending on the destination.

We will provide our customers with a tracking number and regular updates on the shipping status of their order. Our customer service team will also be available to assist with any inquiries or concerns regarding the shipment.

At the destination, our customers can expect the product to be delivered to their specified address and unloaded by the carrier. We recommend our customers to carefully inspect the product upon delivery and report any damages or issues to us immediately.

We are committed to providing our customers with high-quality products and services, and we strive to ensure that the Multi Disc Screw Press arrives at its destination in perfect condition.

Thank you for choosing our product. We look forward to serving you!